Controls

Providing design, integration, and start up services for fully integrated and interoperable enterprise-level control platforms.

Understanding the processes being controlled and designing the right solution to meet the client’s desired system performance is the foundational objective of our Controls Engineering Teams.

We provide comprehensive solutions from control system design through programming and startup, and routinely work with process engineers, contractors and owners to help deliver successful projects. The Controls Team understands the disparate system types found in many operational facilities, and designs and commissions fully integrated and interoperable enterprise-level control platforms.

Controls Services

Control Systems Engineering

- Creating P&IDs and associated process control narrative for overall system functionality

- Control panel layouts, bills of materials, and schematics that meet UL standards

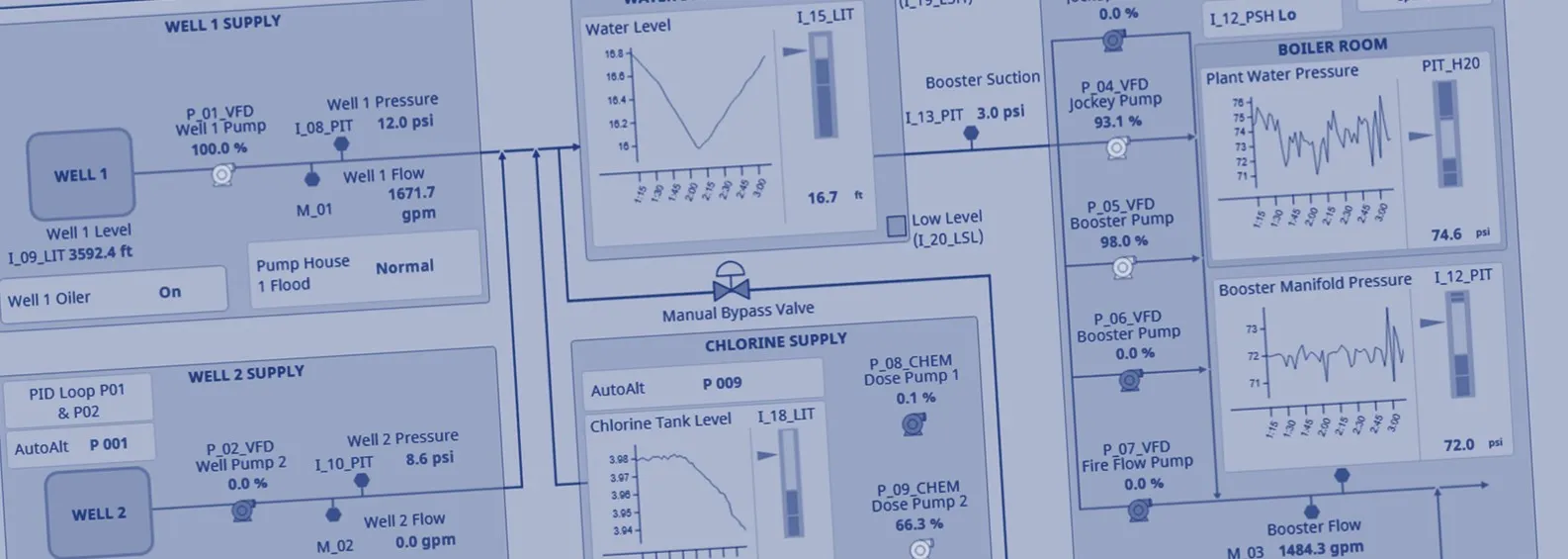

- Specifying SCADA software and hardware

- Preparing detailed instrumentation and control specifications

- Creating detailed designs and engineering plans for control systems to ensure reliable systems that are easily constructable.

- Planning scalable control network architectures for secure and reliable control systems

Control Systems Integration

- Writing/Testing programs for PLCs

- Creating/Implementing SCADA systems and HMIs of many platform types

- Robust library of custom objects for consistent integration of logic & visualization platforms

- Ongoing maintenance and technical support for control systems

- Integrating various technologies to enhance productivity, safety, and streamline

- Modernizing/Migrating legacy PLC and SCADA systems

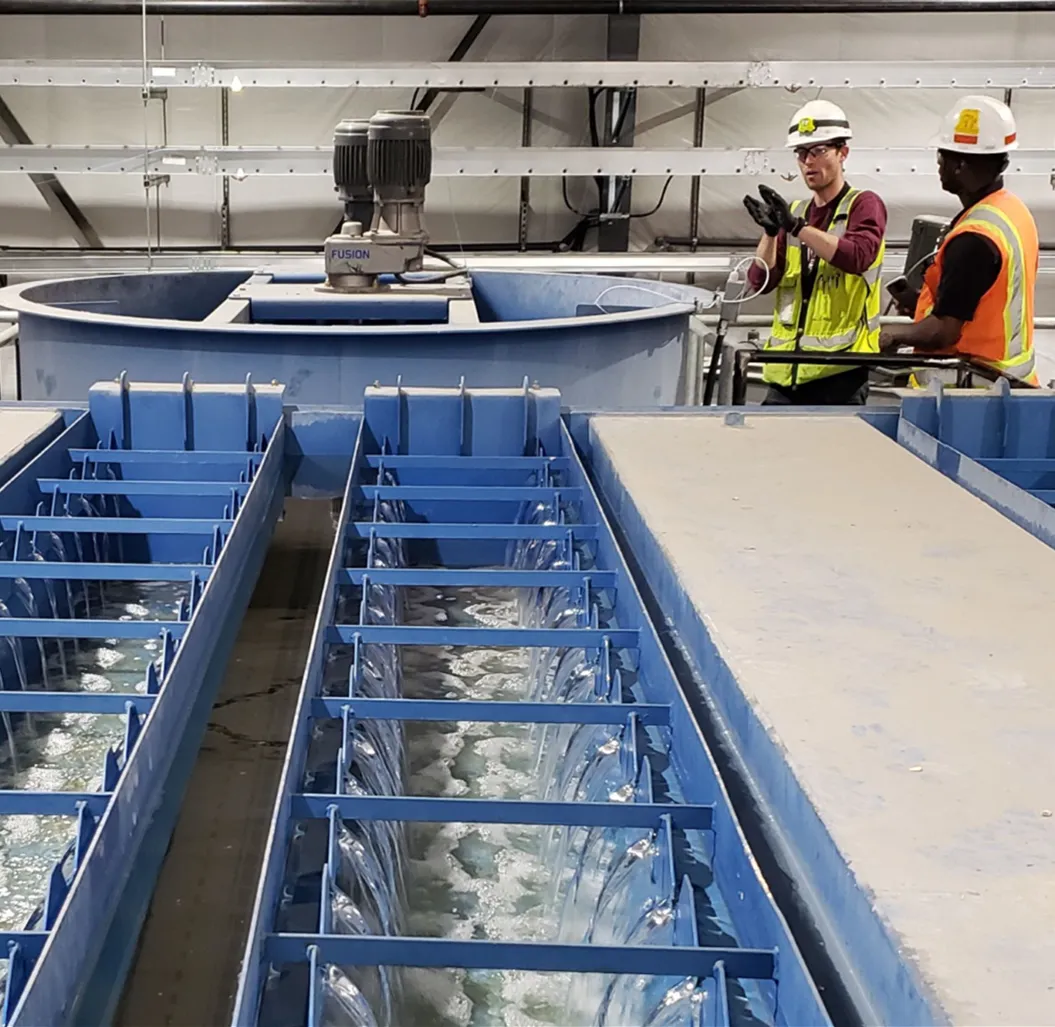

- Onsite system startups, including I/O and functional testing, and initializing equipment/instrumentation

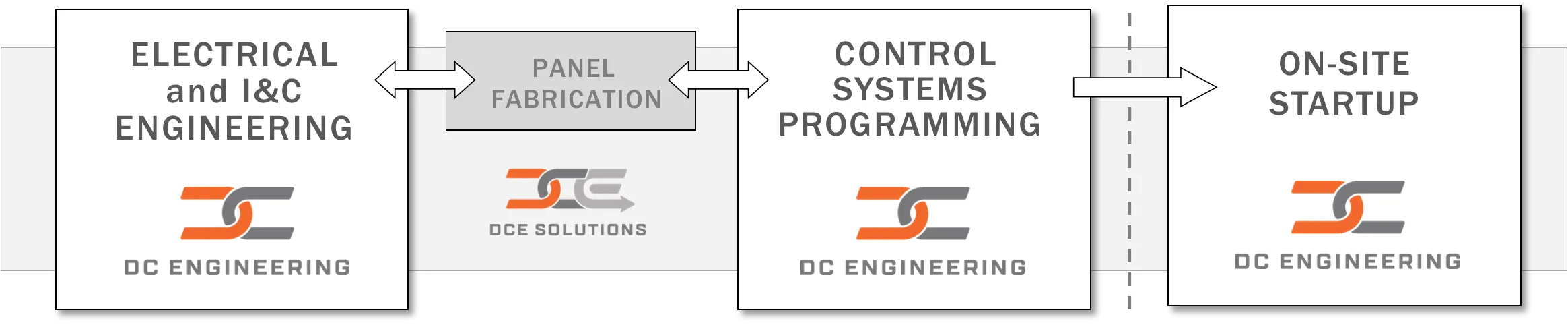

Control System Design and Control Panel Construction & Testing Under One Roof

The Controls Team works closely with DCE Solutions, DC Engineering’s subsidiary that builds and tests control panels, as well as providing other hardware solutions. Alignment between these teams enables 2 important factors: (1) panels are actually built based on control system design, and (2) panels are configured and tested before the arrive on the job site.

Example Clients

Facility wide controls engineering, systems integration, control panels, start-up, and ongoing support for a Texas cheese and whey manufacturing plant.

Facility wide SCADA, mining process controls, control panel design & integration, system startup and ongoing support for a water treatment plant at this Nevada gold mine.

Design, systems integration, and start up services for a manufacturing plant effluent system to meet municipal wastewater pretreatment requirements.

Partnerships and Certifications